If you’ve ever wondered, what size table saw do I need? fret not, because I’ve got you covered. Choosing the right table saw size is crucial for a smooth and efficient woodworking experience. So, let’s embark on this exciting journey together as we explore the answer to your question Let the sawdust fly and the creativity flow.

Determining the right size table saw depends on several factors such as Your Project Requirements, Types of Table Saws, Blade Diameter, Rip Capacity, Available Space, Portability, Budget, and Safety Features.

Additionally, consider the portability and safety features that align with your needs. By carefully evaluating these factors, you can confidently choose a table saw that best fits your woodworking requirements, ensuring both efficiency and safety in your projects.

What size table saw is suitable for my woodworking projects?

Selecting the appropriate size table saw for your woodworking projects is crucial for efficient and precise work. Consider the following factors to determine the right size:

- Project Scope: Assess the size and complexity of your typical woodworking projects. If you frequently work with large sheets of plywood or thick lumber, a table saw with a larger rip capacity and a larger work surface might be more suitable.

- Blade Diameter: Table saws come with different blade diameters, typically ranging from 8 inches to 12 inches. Larger blades are ideal for making deeper cuts and handling thicker materials, while smaller blades are better for finer, intricate cuts.

- Rip Capacity: The rip capacity refers to the maximum distance between the blade and the fence. It determines the width of the cut you can make. Ensure the table saw’s rip capacity can handle the width of the materials you commonly use in your projects.

- Available Space: Measure the available space in your workshop or workspace. Larger table saws require more room for proper operation and safety. Choose a size that fits comfortably within your workspace.

- Portability: If you have limited space or need to transport your table saw frequently, consider a compact or portable model. These options are more mobile and easier to store.

- Budget: Determine your budget for the table saw. Table saws come in various price ranges, and choosing a size that suits your needs while fitting within your budget is essential.

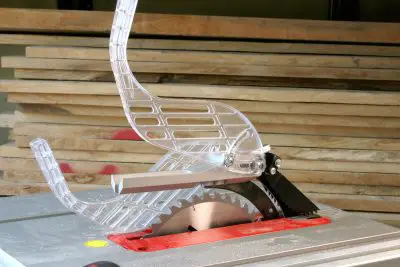

- Safety Features: Look for a table saw with essential safety features like a blade guard, anti-kickback pawls, and a riving knife. These features help prevent accidents and ensure safe woodworking.

By carefully evaluating these factors and understanding your specific woodworking needs, you can confidently select the right size table saw that will enhance the efficiency and precision of your projects, while also ensuring a safe and enjoyable woodworking experience.

How do I determine the right table saw size for my needs?

Selecting the right table saw size is crucial for any woodworking enthusiast or professional, as it directly impacts the efficiency and precision of your projects. With a wide range of options available, it can be overwhelming to determine the best fit for your specific needs. Here is how to determine the right table saw size for my needs:

- Available Space: Assess the available space in your workshop or workspace where the table saw will be placed. Measure the dimensions carefully, including the floor area and the height of the ceiling, to ensure the chosen table saw fits comfortably without hindering movement.

- Types of Projects: Consider the types of projects you plan to undertake. For smaller, more straightforward tasks, a compact table saw might suffice. However, if you anticipate handling larger, more complex projects, a full-size table saw with greater rip capacity and workspace will be more suitable.

- Blade Size: Table saws come with various blade sizes, typically ranging from 8 to 12 inches. A larger blade size allows for deeper cuts and accommodates thicker materials. If you plan to cut large pieces of lumber frequently, a table saw with a larger blade size will be more efficient.

- Rip Capacity: The rip capacity refers to the maximum distance between the blade and the fence. It determines the width of the material you can cut. Consider the largest width you may need to cut in your projects and choose a table saw with a rip capacity that accommodates that size comfortably.

- Power and Motor: The power and motor of a table saw play a crucial role in its performance. More powerful motors provide smoother cuts and can handle denser materials. Choose a table saw with sufficient horsepower to tackle the materials you work with regularly.

- Portability: If you have limited space or foresee the need to move the table saw frequently, consider a portable or compact model. These table saws are lighter and often come with wheels for easy transportation.

- Safety Features: Prioritize safety features when selecting a table saw. Look for models with blade guards, riving knives, anti-kickback pawls, and a reliable safety switch. Safety should never be compromised in any woodworking tool.

- Budget: Determine your budget range before making a decision. While larger and more feature-rich table saws may offer greater capabilities, they can also come at a higher cost. Strike a balance between your needs and budget constraints

What factors should I consider when choosing a table saw size?

When selecting the right table saw size, several crucial factors should be considered to ensure it meets your specific needs and requirements. Below are the key factors to keep in mind when choosing a table saw size:

- Available Space: Assess the dimensions of your workshop or workspace where the table saw will be placed. Measure the floor area and height of the ceiling to ensure the chosen table saw fits comfortably without hindering movement or causing any space constraints.

- Types of Projects: Consider the types of woodworking projects you plan to undertake. Smaller, compact table saws are suitable for basic tasks and limited workspace, while larger, full-size table saws with more power and capacity are ideal for handling larger and more complex projects.

- Blade Size: Table saws come with various blade sizes, typically ranging from 8 to 12 inches in diameter. A larger blade size allows for deeper cuts and can accommodate thicker materials. If you anticipate working with substantial stock or dense materials, opt for a table saw with a larger blade size.

- Rip Capacity: The rip capacity refers to the maximum distance between the blade and the fence. It determines the width of the material you can cut. Consider the widest pieces you may need to cut in your projects and choose a table saw with a rip capacity that comfortably accommodates that size.

- Motor Power: The motor power is a critical factor that affects the performance and cutting capabilities of the table saw. More powerful motors provide smoother cuts and can handle dense or hardwood materials more effectively. Choose a table saw with sufficient horsepower to handle the materials you work with regularly.

- Portability: If you have limited space or foresee the need to move the table saw frequently, consider a portable or compact model. These table saws are lighter in weight and often come with wheels for easy transportation.

- Safety Features: Prioritize safety features when selecting a table saw. Look for models with blade guards, riving knives, anti-kickback pawls, and a reliable safety switch. Safety should never be compromised in any woodworking tool.

- Budget: Determine your budget range before making a decision. Table saws come in a wide price range, and more feature-rich models may come at a higher cost. Striking a balance between your needs and budget constraints is essential.

- User Experience: Consider the ease of use and user-friendly features of the table saw. Look for convenient adjustments, easy-to-read scales, and smooth fence movement to enhance your overall woodworking experience.

- Reviews and Recommendations: Research customer reviews and seek recommendations from experienced woodworkers or professionals who have used the specific table saw models you are considering. This can provide valuable insights into the performance and reliability of the product.

By carefully considering these factors, you can make an informed decision and choose the right table saw size that perfectly suits your woodworking needs and enhances your overall productivity and creativity in the workshop.

Is a compact or larger table saw better for my workshop?

Determining whether a compact or larger table saw is better for your workshop depends on various factors and your specific woodworking needs. Below is direct information to help you make an informed decision:

Compact Table Saw:

Pros:

- Space-saving: Compact table saws are ideal for smaller workshops or limited workspace. They take up less floor space and are easier to maneuver in tight areas.

- Portability: Being lightweight and smaller in size, compact table saws are more portable, making them suitable for woodworkers who need to move their equipment frequently or work on job sites.

- Cost-effective: Compact table saws are generally more affordable than larger, professional-grade models, making them a budget-friendly option for hobbyists and beginners.

Cons:

- Limited Capacity: Compact table saws often have smaller rip capacities and may not handle larger stock or heavy-duty projects as effectively as larger models.

- Less Power: They usually come with lower horsepower motors, which may result in less cutting power and slower performance when working with dense materials.

Larger Table Saw:

Pros:

- Increased Capacity: Larger table saws offer more substantial rip capacities, enabling you to handle larger pieces of lumber and work with more significant materials.

- Greater Power: Larger table saws typically feature more powerful motors, providing smoother cuts and better performance when cutting dense or hardwood materials.

- Versatility: These saws are well-suited for a wide range of woodworking projects, including professional and heavy-duty tasks.

Cons:

- Space Requirements: Larger table saws demand more floor space in your workshop, limiting movement and potentially requiring rearrangement of your workspace.

- Higher Cost: Professional-grade, larger table saws often come with more features and capabilities, but they can also be more expensive than compact models.

Which one is better for your workshop?

- If you have a small workshop with limited space and you primarily work on smaller projects or hobbyist tasks, a compact table saw could be the better option for you.

- On the other hand, if you have a spacious workshop, work on larger or professional projects, and require more cutting capacity and power, a larger table saw would be a more suitable choice.

Ultimately, the decision should align with your budget, available space, and the type of woodworking projects you undertake regularly. Consider your current and future woodworking needs, and select the table saw that best complements your requirements, helping you achieve precise and efficient cuts in your workshop.

What size table saw is ideal for a beginner woodworker?

For a beginner woodworker, choosing the right size table saw is crucial to ensure a positive and productive woodworking experience. A table saw that strikes a balance between functionality, safety, and ease of use is ideal. Here’s direct information to help you determine the size that suits a beginner woodworker:

- Compact or Benchtop Table Saw: For most beginner woodworkers, a compact or benchtop table saw is a great starting point. These table saws are smaller in size and designed to be placed on a workbench or stand. They offer the following advantages:

- Space-saving: Compact table saws are suitable for smaller workshops or limited workspace.

- Portability: They are lightweight and easy to move around, making them convenient for woodworking enthusiasts who might not have a dedicated workshop.

- User-friendly: Benchtop saws often come with simplified controls and are more beginner-friendly for those new to woodworking.

- Budget-friendly: Compact table saws are generally more affordable compared to larger, professional-grade models, making them accessible to beginners.

- Blade Size: As a beginner, a table saw with an 8 to 10-inch blade is sufficient for most projects. These blade sizes are versatile and can handle a wide range of cuts commonly encountered in woodworking.

- Rip Capacity: Look for a table saw with a rip capacity of around 24 inches or more. This width allows you to cut standard-size sheet materials and handle basic woodworking tasks effectively.

- Safety Features: Prioritize safety when selecting a table saw. Look for models with blade guards, riving knives, anti-kickback pawls, and a reliable safety switch. Safety should always be a top consideration, especially for beginners.

- Motor Power: A table saw with a motor ranging from 1.5 to 2 horsepower is sufficient for most beginner projects. This power range allows you to cut through softwood and plywood without difficulty.

- User Reviews: Research customer reviews and seek recommendations from experienced woodworkers to gain insights into the performance, reliability, and ease of use of the table saws you are considering.

How does the size of the material I work with affect my table saw choice?

The size of the material you work with significantly influences your table saw choice and determines the efficiency and precision of your woodworking projects. Consider the following points to understand how material size impacts your table saw selection:

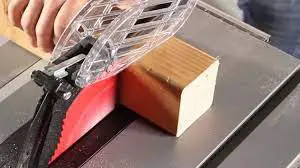

Rip Capacity: The rip capacity of a table saw refers to the maximum distance between the blade and the fence. It determines the width of the material you can cut.

When working with larger materials, such as plywood sheets or wide boards, you need a table saw with a sufficient rip capacity to accommodate the material’s width. Choosing a table saw with an inadequate rip capacity may limit your ability to make accurate cuts or require multiple passes, affecting the quality of your work.

Blade Size: Table saws come with various blade sizes, typically ranging from 8 to 12 inches in diameter. Larger blade sizes allow for deeper cuts and can handle thicker materials. If you frequently work with thick hardwood or dense materials, a table saw with a larger blade size is essential to ensure smooth and efficient cutting.

Motor Power: The power of the table saw’s motor is crucial when working with larger or denser materials. A more powerful motor provides the torque and cutting force needed to handle challenging cuts, reducing the risk of blade stalling or bogging down during the operation. Insufficient motor power may lead to compromised cutting performance and potential safety issues.

Table Size: The size of the table itself impacts the stability and support for your workpieces. For larger materials, you need a table saw with a spacious and sturdy work surface to handle the material without tipping or causing imbalance during cutting.

Portability: If you frequently work with large materials on job sites or in different locations, portability becomes a crucial factor. Portable table saws with folding stands or wheels offer convenience and ease of transportation when handling larger materials away from your workshop.

Cutting Accuracy: The size of the material can influence the precision of your cuts. A larger table saw with a more extensive work area allows you to maintain better control and stability over sizable workpieces, leading to more accurate cuts.

Safety Considerations: Working with larger materials may require more attention to safety. Ensure the table saw you choose has appropriate safety features, such as blade guards, riving knives, and anti-kickback pawls, to protect you during cutting.

Are there specific projects that require a certain table saw size?

Yes, specific woodworking projects may require a certain table saw size to ensure efficient and precise cutting. The size and capabilities of the table saw play a crucial role in handling different project types. Here are some examples of projects and the corresponding table saw size that works best for each:

- Cabinet Making: Cabinet-making projects often involve working with large sheets of plywood or MDF. To handle these materials effectively and make accurate cuts, a table saw with a substantial rip capacity, typically 30 inches or more, is ideal. A larger table saw with a powerful motor can also handle thicker hardwood used for cabinet frames.

- Furniture Building: Furniture projects vary in size and complexity. For smaller furniture pieces, a table saw with a medium-sized blade (10 inches) and a moderate rip capacity (around 24 inches) can suffice. However, larger furniture items or custom pieces may require a table saw with a larger rip capacity and blade size to accommodate wider boards and thicker materials.

- Flooring Installation: When cutting flooring materials like hardwood or laminate, a table saw with a larger rip capacity is essential to handle long and wide planks. Additionally, a table saw with a miter gauge and adjustable bevel angle capability is valuable for making precise angle cuts required in flooring installation.

- Trim Work: For trim work and molding projects, a table saw with a precise miter gauge and the ability to make bevel cuts is crucial. Compact or benchtop table saws with a smaller blade size can be sufficient for most trim work tasks.

- Small DIY Projects: For small DIY projects or craftwork, a compact or benchtop table saw with an 8 to 10-inch blade size and moderate rip capacity can handle a wide range of materials commonly used in DIY home projects.

- Rip-Cutting Lumber: Projects that involve frequent rip-cutting of standard-sized lumber, such as framing or basic construction tasks, can be accomplished with a table saw featuring a standard blade size (10 inches) and a medium rip capacity (around 24 inches).

- Resawing: Resawing involves cutting thicker boards or logs into thinner pieces. To achieve resawing cuts accurately, a table saw with a larger blade size (12 inches) and a powerful motor is recommended.

It is essential to match the table saw size and capabilities with the specific requirements of your projects. While larger table saws offer more versatility and handling capacity for substantial projects, compact models may suffice for smaller or occasional tasks. Always prioritize safety features and choose a table saw that aligns with your budget and intended

What are the advantages of a larger table saw for professional woodworkers?

Professional woodworkers often demand powerful and versatile tools to handle complex and large-scale projects efficiently. Among these tools, a larger table saw can significantly enhance their capabilities and productivity. Hee is the advantages of a larger table saw for professional woodworkers.

- Increased Rip Capacity: Larger table saws typically offer a more extensive rip capacity, allowing professional woodworkers to cut wider and larger materials with ease. This feature is especially beneficial for handling large sheets of plywood or cutting thick hardwood for furniture and cabinetry.

- Greater Cutting Depth: A larger table saw with a larger blade size provides increased cutting depth. This capability is essential when dealing with thick stock or resawing tasks, allowing professional woodworkers to make deeper and precise cuts in a single pass.

- Enhanced Stability: The larger size of the table and the added weight of a larger table saw contribute to better stability and reduced vibration during cutting. This improved stability results in more accurate cuts and a smoother woodworking experience.

- Power and Performance: Larger table saws are equipped with more powerful motors, providing higher horsepower and torque. This increased power enables professional woodworkers to cut through dense and hardwood materials effortlessly, resulting in faster and more efficient work.

- Versatility: Professional woodworkers often encounter a wide range of projects with diverse material types and sizes. A larger table saw offers enhanced versatility, allowing them to tackle various tasks, from fine detail work to heavy-duty cutting.

- Precision and Accuracy: The larger work surface and improved fence systems in bigger table saws contribute to better precision and accuracy in cutting. This level of accuracy is essential for ensuring a perfect fit and seamless assembly in professional-grade projects.

- Safety Features: Larger table saws often come with advanced safety features such as riving knives, blade guards, and anti-kickback devices. These safety mechanisms offer enhanced protection for professional woodworkers during their demanding cutting operations.

- Dust Collection: Professional woodworkers typically work on larger projects for extended periods. Larger table saws often have more efficient dust collection systems, which help keep the workspace cleaner and healthier by effectively capturing sawdust and debris.

Can a smaller table saw handle heavy-duty cutting tasks effectively?

While smaller table saws can handle a variety of cutting tasks, their effectiveness in heavy-duty cutting depends on several factors. Smaller table saws have their limitations and may not be the best choice for consistently tackling heavy-duty cutting tasks. Here are some key considerations:

- Motor Power: Smaller table saws generally come with lower horsepower motors compared to larger, more powerful models. The reduced motor power can result in slower cutting speeds and may struggle when cutting through dense or thick materials regularly.

- Rip Capacity: The rip capacity of smaller table saws is limited compared to larger ones. This restricts the width of materials that can be cut. For heavy-duty tasks involving wide or large sheets of plywood, the limited rip capacity may be insufficient, leading to more challenging and time-consuming cutting processes.

- Cutting Depth: Smaller table saws typically have a shallower cutting depth compared to larger models. This limitation can be a hindrance when attempting to cut through thick stock or performing resawing tasks that require deeper cuts.

- Stability and Durability: Heavy-duty cutting tasks put more stress on the table saw’s components. Smaller table saws may lack the same level of stability and durability needed for consistent heavy-duty use. Frequent heavy cutting can lead to increased wear and tear, affecting the table saw’s performance and longevity.

- Safety Considerations: When dealing with heavy-duty cutting tasks, safety becomes even more critical. Smaller table saws may have fewer safety features compared to larger, professional-grade models. Ensuring the safety of the operator during heavy-duty cutting operations is essential.

While smaller table saws can handle occasional heavy-duty cutting tasks, they are not designed for sustained, high-volume use in such applications. For professional woodworkers or those frequently working on heavy-duty projects, investing in a larger, more robust table saw with a higher horsepower motor, larger rip capacity, and deeper cutting depth is recommended.

Should I prioritize portability or table size when selecting a saw?

When selecting a saw, whether to prioritize portability or table size depends on your specific woodworking needs and usage scenarios. Consider the following factors to make an informed decision:

Prioritize Portability If:

- Job Site Usage: If you frequently work on job sites or need to move your saw between different locations, portability should be a top priority. Compact and portable saws with folding stands or wheels offer convenience and ease of transportation.

- Limited Workshop Space: If your workshop has limited space, a portable saw that can be easily stored or moved out of the way when not in use is advantageous.

- DIY Projects: For hobbyists and DIY enthusiasts who work on smaller projects and occasional woodworking tasks, a portable saw is often sufficient and more budget-friendly.

- Versatility: Portable saws are versatile and can be used in various settings, making them suitable for those who need a saw that can adapt to different woodworking environments.

Prioritize Table Size If:

- Large Woodworking Projects: If you frequently work on larger woodworking projects, a table saw with a larger table size provides better support and stability for handling sizable materials.

- Precision and Accuracy: A larger table size allows for more precise and accurate cuts, especially when working on detailed or complex woodworking projects.

- Heavy-Duty Cutting: If you regularly undertake heavy-duty cutting tasks, a larger table saw with a robust build and more powerful motor can handle these tasks more effectively.

- Professional Use: For professional woodworkers or those who rely on their table saw for income, a larger table saw with increased cutting capacity ensures efficiency and productivity for a wide range of projects.

- Resawing and Sheet Material Cutting: A larger table size and rip capacity are essential for resawing thick boards and cutting large sheets of plywood or MDF.

What safety considerations are tied to the size of the table saw?

The size of the table saw can influence several safety considerations that woodworkers should be aware of. Here are the safety aspects tied to the size of the table saw:

- Blade Size and Cutting Depth: Larger table saws often come with larger blades, which can result in deeper cutting depths. This poses an increased risk of severe injuries if not used with caution. Operators must be attentive and follow proper safety procedures to prevent accidental contact with the blade during cutting.

- Increased Power: Larger table saws typically have more powerful motors to handle heavy-duty cutting tasks. The higher horsepower and cutting capacity require greater attention and control when operating the saw to avoid kickback or loss of control.

- Stability and Weight: Larger table saws are generally heavier and offer better stability during cutting. However, the weight can also make it more challenging to move or adjust the saw, so operators must take care to avoid accidents or strain when repositioning the tool.

- Space Requirements: Larger table saws demand more floor space in the workshop, potentially leading to overcrowding if the workspace is limited. Adequate space around the saw is crucial to ensure safe movement and handling of materials during cutting.

- Safety Features: Larger table saws often come equipped with advanced safety features, such as blade guards, riving knives, and anti-kickback devices. These features help protect the operator from potential hazards and reduce the risk of accidents.

- Material Handling: With larger table saws, operators may be cutting bigger and heavier materials. Proper material handling techniques are essential to maintain balance and control while feeding the material into the blade safely.

- Operator Experience: Operating larger table saws requires a certain level of experience and skill due to their increased power and cutting capacity. Beginners or inexperienced operators should exercise extra caution and consider additional training before using larger table saws.

- Dust Collection: Larger table saws generate more sawdust and debris during cutting. Proper dust collection and ventilation are important to maintain a clean and safe working environment and prevent respiratory issues.

How does the price vary between different sizes of table saws?

The price of table saws can vary significantly based on their size and features. Generally, larger table saws with more capabilities tend to be more expensive than smaller, more basic models. Here’s how the price varies between different sizes of table saws:

- Compact or Benchtop Table Saws: Compact table saws with smaller table sizes and basic features are typically the most affordable option. These saws are suitable for hobbyists, DIY enthusiasts, or those with limited woodworking needs and budgets.

- Contractor Table Saws: Contractor table saws, with larger table sizes and more powerful motors, are the mid-range option in terms of price. They offer better cutting capacity and features compared to compact saws, making them suitable for moderate woodworking tasks.

- Hybrid Table Saws: Hybrid table saws fall between contractor and cabinet saws in terms of price and capabilities. They offer a balance between power, size, and affordability, making them a popular choice for serious hobbyists and small woodworking businesses.

- Cabinet Table Saws: Cabinet table saws, with the largest table sizes, most powerful motors, and advanced features, are the most expensive category. They are designed for professional woodworkers and industrial use, handling heavy-duty and high-volume cutting tasks.

Factors that can Influence Price Variation:

- Size and Power: Larger table saws with more powerful motors tend to cost more due to their increased cutting capacity and capability to handle dense or thick materials.

- Construction and Build Quality: Higher-priced table saws often feature more durable materials and precision engineering, ensuring better performance and longevity.

- Additional Features: Saws with advanced features like built-in dust collection systems, improved fence systems, digital displays, and safety enhancements can command a higher price.

- Brand Reputation: Well-established brands with a reputation for quality and reliability may have higher-priced table saws compared to lesser-known brands.

- Warranty and Support: Table saws with longer warranties and better customer support may have a higher price tag due to the added peace of mind and after-sales service.

Are there any limitations to the type of cuts based on table saw size?

The size of the table saw can impose certain limitations on the type of cuts you can make. The table saw’s size, along with its rip capacity and cutting depth, affects the range of cuts you can perform effectively. Here are the limitations to the type of cuts based on table saw size:

- Crosscuts on Wide Materials: Smaller table saws with limited table size and rip capacity may struggle to make accurate crosscuts on wide materials, such as large plywood sheets or wide boards. This limitation can result in less precise cuts and may require additional support or repositioning of the material during cutting.

- Ripping Wide Boards: Smaller table saws may have a limited rip capacity, making it challenging to rip wide boards into narrower strips in a single pass. This limitation could lead to multiple passes and require more effort to achieve the desired width.

- Bevel Cuts: Some compact or benchtop table saws may have limited bevel cutting capacity due to their design and smaller blade size. This can restrict the angle range for bevel cuts, making it less suitable for certain woodworking projects that require complex beveling.

- Cutting Thick Stock: Smaller table saws may have shallower cutting depths, limiting their ability to cut through thick stock or handle resawing tasks effectively. This can be a significant limitation when working with thicker materials or making deep cuts.

- Cutting Large Dados: Creating wide and deep dados or grooves in the material might be challenging on smaller table saws due to their limited cutting capacity and motor power.

- Handling Heavy-Duty Cutting: Heavy-duty cutting tasks, such as cutting hardwoods or dense materials consistently, may strain smaller table saws with lower horsepower motors, potentially affecting cutting performance and safety.

- Precision on Long Cuts: Longer cuts on large materials might be less accurate on smaller table saws due to the reduced stability and support offered by the smaller table surface.

It’s essential to consider your woodworking projects and the type of cuts you frequently perform when selecting a table saw. Larger table saws with more substantial rip capacity, cutting depth, and power generally offer more versatility and can handle a broader range of cutting tasks. However, smaller table saws can still be adequate for basic woodworking tasks and smaller projects, especially for hobbyists and DIY enthusiasts.

Can I achieve precision and accuracy with both small and large table saws?

Yes, precision and accuracy can be achieved with both small and large table saws. The key factors influencing precision and accuracy are not solely dependent on the size of the table saw but also on various other considerations:

- Blade Quality: The quality and sharpness of the saw blade are crucial for achieving precise and accurate cuts. Using high-quality, well-maintained blades on both small and large table saws can significantly enhance cutting precision.

- Fence and Miter Gauge: A stable and accurate fence system, along with a reliable miter gauge, is essential for making straight and precise cuts. Both small and large table saws can have well-designed and calibrated fence and miter gauge systems.

- Operator Skill: The skill and experience of the operator play a significant role in achieving precise and accurate cuts. Regardless of the table saw size, a skilled operator can control the material feed, maintain consistent pressure, and make precise adjustments for better cutting results.

- Setup and Calibration: Proper setup and calibration of the table saw are essential for achieving accuracy. Aligning the blade, fence, and miter gauge accurately ensures that the cuts are square and true.

- Material Support and Handling: Adequate material support and proper handling during cutting contribute to precision. Whether using a small or large table saw, using appropriate support and techniques can lead to more accurate cuts.

- Stability and Vibration Control: Reducing vibration and ensuring stability during cutting are crucial for precision. Both small and large table saws can be stabilized using anti-vibration pads or securely mounted to a stable work surface.

- Cutting Speed: Controlling the cutting speed and feeding the material at a consistent rate can impact the quality of the cut. This applies to both small and large table saws.

- Safety Considerations: A focus on safety is vital to maintain precision and accuracy. Accidents or sudden interruptions during cutting can lead to inaccuracies and compromised results.

While larger table saws may offer certain advantages such as increased cutting capacity and stability, small table saws can still achieve precise and accurate cuts with proper setup, operator skill, and attention to detail. Many skilled woodworkers achieve excellent results with both types of saws, tailoring their choices to match the specific requirements of their projects and available workspace.

Recommended:

- How much does a washing machine weigh?

- What size flange do i need?

- What size water heater do i need?

Conclusion

So, what size table saw do you need? The answer lies in aligning your woodworking needs with the available options. Whether you opt for a compact table saw for mobility or a larger one for increased capacity, consider blade size, rip capacity, motor power, and safety features to make an informed decision.

Remember, the perfect fit for your woodworking projects is within reach. Invest in the right table saw, and let your creative journey in the workshop reach new heights.