What size bilge pump do I need? When it comes to ensuring the safety and well-being of your boat, a bilge pump plays a crucial role. The last thing any boat owner wants is water flooding the interior, jeopardizing the vessel and its occupants. To prevent such a scenario, having a reliable bilge pump is essential.

As a general rule of thumb, you should aim to pump out at least 1% of your boat’s volume per minute. So, if you have a 20-foot boat, you would need a pump that can pump out at least 2 gallons per minute. If you have a high-performance boat or a boat that is likely to take on a lot of water, you may need a larger pump.

In this guide, we will walk you through the factors to consider when choosing the right size bilge pump, providing you with the knowledge needed to keep your vessel dry and secure on the water.

What size bilge pump do i need?

The size of bilge pump you need depends on the size of your boat, the amount of water it can hold, and how quickly you need to pump out the water.

Here’s a general rule of thumb:

- For boats up to 25 feet, a 1/2-horsepower pump should be sufficient.

- For boats between 25 and 40 feet, a 1-horsepower pump is recommended.

- For boats over 40 feet, a 2-horsepower pump is necessary.

You’ll also need to consider the rate at which the pump can remove water. A good rule of thumb is to get a pump that can remove water at a rate of 1 gallon per minute for every 10 feet of boat length.

Factors determining the right bilge pump size for your boat?

Selecting the right bilge pump size for your boat involves considering several important factors. Each boat’s unique characteristics and intended use will influence the pump’s capacity and efficiency.

Here are the key factors to consider:

- Boat Size and Type: The size and type of your boat directly influence the amount of water it can hold. Larger vessels typically require more powerful bilge pumps to handle potential water ingress efficiently.

- Displacement: Consider your boat’s displacement, which refers to the weight of water displaced by the hull. A boat with higher displacement may require a more substantial bilge pump to handle any flooding effectively.

- Pumping Capacity: The pumping capacity, usually measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much water the bilge pump can remove within a specific time. Select a pump with a capacity that matches or exceeds the rate at which water can enter your boat.

- Automatic vs. Manual: Bilge pumps come in both automatic and manual versions. Automatic pumps have built-in float switches that activate the pump when water levels rise, providing continuous protection without constant monitoring. Manual pumps, on the other hand, require manual activation and are better suited as backup pumps.

- Number of Pumps: Depending on the boat’s size and importance, you may consider installing multiple bilge pumps. This redundancy ensures a backup pump is available if the primary one fails.

- Power Source: Bilge pumps can be powered by the boat’s electrical system or manually operated. Consider your power source and ensure it can handle the pump’s electrical requirements, or opt for a manual pump if electrical power is unreliable.

- Float Switch Type: If choosing an automatic pump, the type of float switch matters. The most common types are vertical float switches and electronic pressure switches. Each has its advantages and installation considerations.

- Maximum Head Height: The maximum head height is the vertical distance between the bilge pump’s outlet and the discharge point. It’s essential to choose a pump that can handle the head height in your boat’s configuration.

- Wiring and Installation: Proper wiring and installation are crucial for the bilge pump’s functionality and safety. Make sure to follow the manufacturer’s guidelines and, if necessary, seek professional assistance.

- Bilge Capacity and Design: Consider the shape and size of your boat’s bilge area. A pump that fits well and efficiently moves water within your specific bilge design will provide optimal performance.

Remember that bilge pumps are a critical safety feature, and it’s better to err on the side of caution by selecting a slightly larger pump capacity than you think you might need. Regular maintenance and testing of the bilge pump are also vital to ensure it functions as expected when emergencies arise.

How boat size impacts bilge pump requirements?

The size of a boat can have a significant impact on the requirements for bilge pumps. Bilge pumps are essential components of a boat’s bilge system, which is designed to remove excess water that accumulates in the bilge area of the boat. The bilge is the lowest part of the hull, and water can collect there from various sources, such as rainwater, waves, leaks, or condensation.

Here are some ways in which boat size impacts bilge pump requirements:

- Volume of Water Accumulation: Larger boats typically have more interior space, which means they can accumulate a greater volume of water in their bilges. This requires larger capacity bilge pumps to efficiently handle and remove the water to prevent it from affecting the boat’s stability and buoyancy.

- Number of Bilge Pump Units: Larger boats may require multiple bilge pumps strategically placed in different areas of the bilge. Having multiple pumps provides redundancy and ensures that water can be removed effectively, even if one pump fails or becomes overwhelmed.

- Pump Capacity: The capacity of bilge pumps is usually measured in gallons per hour (GPH) or liters per hour (LPH). Larger boats with higher water accumulation potential will require bilge pumps with greater capacity to handle the increased volume effectively.

- Automatic vs. Manual Pumps: Larger boats are more likely to have automatic bilge pumps that turn on automatically when they detect water in the bilge. These pumps are especially useful when the boat is unattended or during emergencies, as they can help keep the boat afloat and reduce the risk of sinking.

- Power Source and Electrical Requirements: Larger bilge pumps may require more electrical power to operate efficiently. This consideration is crucial, as larger boats may have different power systems and battery capacities, and it’s essential to ensure that the bilge pumps do not drain the boat’s power reserves excessively.

- Float Switch Placement: For automatic bilge pumps, float switches are used to activate the pump when the water level rises. The placement and number of float switches will depend on the boat’s size and design to ensure they effectively monitor water levels and trigger the pumps when necessary.

- Manual Backup: While automatic bilge pumps are common in larger boats, having a manual backup bilge pump is a good idea. A manual pump can serve as a secondary option in case the automatic system fails or there is a power outage.

- Emergency Bilge Pumping: In larger boats, it becomes even more critical to have an emergency bilge pumping system, such as a high-capacity portable pump or a dedicated emergency pump. These systems can handle extreme situations and can be instrumental in crisis scenarios.

Does pump location affect size choice?

Yes, the pump location can indeed affect the size choice when it comes to selecting a pump for a particular application. The pump’s location in a system can influence several factors that need to be considered while determining the appropriate pump size.

Here are some key points to understand how pump location can impact size selection:

- Head and Pressure Requirements: The pump’s location in the system affects the total head (pressure) that the pump needs to generate to move the fluid from its source to the destination. If the pump is located far away from the destination or has to lift the fluid to a significant height, it will require more head and may need to be sized accordingly to handle the pressure demands.

- Friction Losses: As the fluid moves through pipes and fittings, there are friction losses, especially over longer distances. If the pump is far away from the point of use, a larger pump might be necessary to compensate for these losses and ensure sufficient flow and pressure at the destination.

- Suction Lift or NPSHA (Net Positive Suction Head Available): If the pump needs to draw the fluid from a lower level or has to work with a suction lift, it will require a certain amount of NPSHA to avoid cavitation (formation of vapor bubbles). If the pump location leads to low NPSHA, a larger pump with better cavitation handling capability may be required.

- Piping System Design: The layout and design of the piping system, including bends, elbows, and restrictions, can influence the pump’s performance. A pump may need to be sized larger to account for these factors if the pump is located in a part of the system where flow restrictions are significant.

- Efficiency and Operating Cost: Pump size and efficiency are related. Running an oversized pump can lead to reduced efficiency and higher operating costs. If the pump location is such that a smaller, more efficient pump can still meet the requirements, it might be a better choice to save energy and reduce costs.

- Space Constraints: In some cases, the pump location might have limited space available, which could impact the size of the pump that can be installed. In such situations, compact or specialized pump designs might be necessary.

It’s essential to carefully assess the system requirements, including the pump’s location and the hydraulic conditions it will encounter, to make an informed decision about the appropriate pump size. A thorough analysis by a qualified engineer or pump specialist will help ensure the pump is properly sized for optimal performance and efficiency.

Guidelines for minimum sizes based on boat size?

When it comes to boats, especially recreational vessels, there are no hard and fast rules dictating the minimum sizes based solely on the boat size. Boat size requirements depend on various factors, including the type of boat, its intended use, local regulations, safety considerations, and personal preferences.

However, there are some general guidelines and considerations to keep in mind when choosing a boat size based on your needs and requirements:

- Number of Passengers: The boat’s size should be able to accommodate the number of passengers you typically intend to carry. Consider the seating capacity and ensure everyone has enough space for a comfortable and safe experience.

- Intended Use: Different boat types serve various purposes. For example, if you plan to go fishing, a smaller boat might suffice, but for extended cruising or overnight trips, a larger boat with more amenities is preferable.

- Safety and Stability: Larger boats generally offer more stability, especially in rough waters. If you intend to venture into open waters or areas with unpredictable conditions, a larger boat might be a safer choice.

- Storage and Amenities: Larger boats provide more storage space for equipment, supplies, and personal belongings. Additionally, they often come with more amenities, such as cabins, galleys, and restrooms.

- Towing and Transport: Consider how you will transport your boat. If you plan to tow it frequently, make sure your vehicle can handle the size and weight of the boat and trailer.

- Budget: Larger boats typically come with higher price tags, both in terms of initial purchase and ongoing maintenance costs. Determine your budget and choose a boat size that fits within it.

- Local Regulations: Be aware of any local regulations or restrictions related to boat size, horsepower, or specific requirements for the body of water you’ll be using.

- Experience and Skill Level: Larger boats might be more challenging to operate, especially for inexperienced boaters. Consider your boating skills and experience when choosing a boat size.

- Resale Value: While not directly related to boat size, larger boats tend to retain their value better than smaller ones.

Remember that the best boat size for you is a balance of all these factors, and there is no one-size-fits-all answer. It’s essential to research different boat types, talk to experienced boaters, visit boat shows, and perhaps even rent or test various boat sizes before making a final decision. This will help you find the boat that suits your needs and preferences best.

Implications of using a pump that’s too large?

Using a pump that’s too large for a particular application can lead to several implications, both in terms of performance and overall system efficiency. Here are some of the main implications of using an oversized pump:

- Energy Inefficiency: An oversized pump may consume more energy than necessary to meet the system’s requirements. Running a pump at partial load or throttling the flow can lead to lower efficiency, resulting in higher operating costs.

- Higher Initial Cost: Larger pumps are generally more expensive than smaller ones. Choosing an oversized pump means investing more money upfront than needed for the desired performance.

- Excessive Flow: An oversized pump can deliver more flow than the system requires. This excess flow can cause issues downstream, such as higher pressure drops, increased wear on components, and potential damage to the system.

- Reduced Control: Oversized pumps might be challenging to control accurately, especially in systems that require precise flow rates. This lack of control can lead to difficulties in maintaining stable processes.

- Cavitation Risk: Running an oversized pump at low flow rates or pressures can increase the risk of cavitation. Cavitation occurs when the pressure drops below the vapor pressure of the liquid, leading to the formation of vapor bubbles that implode and cause damage to the pump.

- Vibration and Noise: An oversized pump operating away from its design point may experience more vibration and generate more noise, affecting the overall system’s comfort and longevity.

- Shortened Pump Life: Constantly operating an oversized pump at partial load can result in additional wear and tear on the pump, potentially shortening its service life.

- Space and Installation Challenges: Larger pumps may require more space for installation and can be cumbersome to handle during installation and maintenance.

- System Instability: In some cases, using an oversized pump can create hydraulic imbalances within the system, leading to erratic performance and reduced stability.

To avoid these implications, it’s essential to carefully size the pump according to the specific requirements of the system. A proper hydraulic analysis, taking into account factors such as head, flow rate, pressure, and system resistance, will help select the right pump size for optimal performance and efficiency.

Consulting with a qualified engineer or pump specialist is highly recommended to ensure the pump meets the system’s needs without unnecessary oversizing.

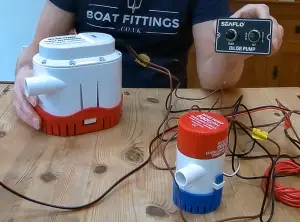

Types of bilge pumps and size differences?

Bilge pumps are essential devices used to remove water that accumulates in the lowest part of a boat’s hull, known as the bilge. There are various types of bilge pumps, each designed for specific applications and capacities. The size differences between these pumps are mainly related to their flow rates or pumping capacities.

Here are some common types of bilge pumps and their size differences:

Submersible Electric Bilge Pump:

-

- Submersible electric bilge pumps are the most common type used in recreational boats.

- They are designed to be placed directly in the bilge water, which allows them to pump water effectively.

- The size differences are usually determined by their pumping capacity, which is typically measured in gallons per hour (GPH) or liters per hour (LPH). Common sizes range from 500 GPH to over 5,000 GPH.

Manual Bilge Pump:

-

- Manual bilge pumps are operated by hand and are suitable as backup pumps or for smaller vessels.

- They are usually compact in size and have a lower pumping capacity compared to electric pumps.

- Common sizes can range from around 15 GPH to 50 GPH.

Diaphragm Bilge Pump:

-

- Diaphragm bilge pumps use a flexible diaphragm to move water.

- They are self-priming and can handle small debris without clogging.

- The size differences are similar to electric bilge pumps, with various GPH ratings available.

Centrifugal Bilge Pump:

-

- Centrifugal bilge pumps use a rotating impeller to move water.

- They are efficient and can handle larger volumes of water.

- The size differences are determined by GPH ratings, ranging from several hundred to several thousand GPH.

High-Capacity Bilge Pump:

-

- High-capacity bilge pumps are heavy-duty pumps designed for larger vessels or situations where significant water needs to be evacuated quickly.

- They have much higher GPH ratings compared to standard bilge pumps.

- High-capacity pumps can have GPH ratings of 10,000 or more.

The choice of bilge pump size depends on the size and type of the boat, the potential for water ingress, and the desired pumping capacity for effective bilge water management.

Larger vessels or those operating in areas with higher risks of water ingress may require larger bilge pumps to handle larger volumes of water effectively. It’s essential to select a bilge pump that matches the specific needs of your boat to ensure efficient water removal and enhance safety on board.

Conclusion

Here, you get to learn more on this topic about what size bilge pump do i need. To determine the appropriate size bilge pump for your boat, consider its size, water ingress risks, required pumping capacity, and manufacturer recommendations to ensure effective water removal and optimal safety on board.