Have you ever wondered how long is 2 inches? 2 inches may seem like a small measurement, but it can be significant in many applications, from woodworking to engineering. Understanding the length of 2 inches and how to measure it accurately is essential for anyone working in these fields or engaging in do-it-yourself projects.

Two inches is equivalent to 5.08 centimeters or 50.8 millimeters. In terms of visual reference, two inches is approximately the length of the top section of an average thumb or the width of a standard paperclip.

In this blog post, we will explore the definition of an inch, the history of the inch as a measurement unit, and how to measure 2 inches accurately using various tools.

We’ll also discuss the significance of 2 inches in different applications, examples of objects that are 2 inches long, and the limitations of using inches as a measurement unit. So let’s dive in and learn more about how long is 2 inches.

What is an inch as a unit of length?

An inch is a unit of length that is commonly used in the United States, United Kingdom, and other countries that have been influenced by British culture. It is a small unit of measurement that is equivalent to 1/12 of a foot or 2.54 centimeters. The inch is abbreviated as “in” or represented by the symbol.

The inch has been in use for hundreds of years and has a long history of being used for measuring things that are relatively small in size. One of the reasons that the inch has been so widely used is that it is a convenient size for measuring things that are often used or handled by humans, such as paper, cloth, and household items.

The inch is a part of the Imperial system of measurement, which was used in the British Empire and its colonies. Today, the inch is still commonly used in the United States and the United Kingdom, although these countries have largely adopted the metric system for scientific and international purposes.

To convert inches to other units of measurement, such as feet or centimeters, you can use conversion factors. For example, there are 12 inches in one foot, so to convert inches to feet, you can divide the number of inches by 12. To convert inches to centimeters, you can multiply the number of inches by 2.54.

Conversion of inches to other units of length

Inches can be converted to other units of length using conversion factors. Here are some common conversions:

1 inch = 0.0833 feet 1 inch = 0.0278 yards 1 inch = 2.54 centimeters 1 inch = 25.4 millimeters

To convert inches to feet, you can divide the number of inches by 12 since there are 12 inches in one foot. For example, if you have 24 inches, you can divide 24 by 12 to get 2 feet.

To convert inches to yards, you can divide the number of inches by 36 since there are 36 inches in one yard. For example, if you have 72 inches, you can divide 72 by 36 to get 2 yards.

To convert inches to centimeters, you can multiply the number of inches by 2.54 since there are 2.54 centimeters in one inch. For example, if you have 10 inches, you can multiply 10 by 2.54 to get 25.4 centimeters.

To convert inches to millimeters, you can multiply the number of inches by 25.4 since there are 25.4 millimeters in one inch. For example, if you have 5 inches, you can multiply 5 by 25.4 to get 127 millimeters.

It’s important to note that when converting between units of length, it’s essential to keep track of the units and to use the appropriate conversion factor to avoid errors.

The use of inches in various fields, such as engineering, construction, and manufacturing

Inches are commonly used in various fields, such as engineering, construction, and manufacturing, particularly in the United States and the United Kingdom.

Here are some examples of how inches are used in these fields:

- Engineering: In engineering, inches are often used to specify the dimensions of mechanical parts, such as screws, bolts, and gears. These parts are typically manufactured to precise tolerances, and using inches allows for accurate measurement and fabrication. Additionally, inches are often used in design drawings and schematics to specify the dimensions of parts and assemblies.

- Construction: In construction, inches are used to specify the dimensions of building materials, such as lumber, pipes, and drywall. For example, a 2×4 piece of lumber is actually 1.5 inches by 3.5 inches in size. Inches are also used to specify the thickness of materials, such as concrete and asphalt, and the spacing between structural components, such as studs and joists.

- Manufacturing: In manufacturing, inches are used to specify the dimensions of machine parts, such as bearings, shafts, and housings. Additionally, inches are used to specify the size and position of holes, slots, and other features in machine parts. Inches are also used in manufacturing to specify the dimensions of products, such as consumer goods and industrial equipment.

While the use of inches is still prevalent in these fields, there has been a shift towards the use of the metric system in recent years.

This is particularly true for scientific and international applications, where the metric system is standard. However, in many industries, particularly those that rely on legacy equipment and tooling, inches remain the primary unit of measurement.

The importance of accuracy in measuring length

Accuracy in measuring length is essential in many applications, particularly in science, engineering, and manufacturing.

Here are some reasons why accuracy is important:

- Precision: Measuring length accurately allows for precise and consistent results. This is particularly important in scientific research and engineering design, where small variations in length measurements can have significant impacts on the final outcome.

- Quality Control: In manufacturing, accuracy in measuring length is critical to ensuring that products meet quality standards. For example, a small variation in the length of a screw or bolt can cause it to fail in use, leading to costly recalls or repairs.

- Safety: Accurate length measurements are important for ensuring safety in construction and other applications. For example, if structural components are not measured accurately, they may not fit together properly, leading to instability and potential collapse.

- Cost Savings: In manufacturing and other industries, accurate length measurements can lead to cost savings by reducing waste and increasing efficiency. For example, accurate measurement of materials can help to reduce scrap and rework, leading to lower costs and increased profitability.

Overall, accuracy in measuring length is critical for ensuring precision, quality, safety, and cost savings in a wide range of applications. It is important to use appropriate measuring tools and techniques to ensure accuracy and to verify measurements using multiple methods whenever possible.

Common tools used to measure inches, such as rulers and calipers

There are several tools commonly used to measure inches, including rulers and calipers. Here’s a brief overview of these tools:

- Rulers: A ruler is a flat, straight tool that is used to measure length. Rulers are typically made of plastic, metal, or wood and are marked with units of measurement, including inches and centimeters. To measure length using a ruler, place the end of the ruler against one end of the object being measured and read the measurement at the other end of the object.

- Calipers: A caliper is a more precise tool used to measure length, thickness, or diameter. There are two main types of calipers: digital and analog. Digital calipers have a digital readout that displays the measurement, while analog calipers use a scale and pointer to indicate the measurement. Calipers are often used in manufacturing and engineering applications, where precise measurements are critical.

- Tape measure: A tape measure is a flexible, retractable tool used to measure length. Tape measures typically have markings in both inches and centimeters and are useful for measuring large objects or distances. To measure length using a tape measure, extend the tape measure to the desired length and read the measurement off the tape.

- Micrometer: A micrometer is a precision measuring tool used to measure small distances, typically to within a thousandth of an inch. Micrometers consist of a calibrated screw and a thimble and are often used in manufacturing and engineering applications.

- Laser distance measure: A laser distance measure uses laser technology to measure distance accurately and quickly. It is often used in construction and real estate applications.

Overall, these tools are essential for accurately measuring inches and are commonly used in many different industries and applications.

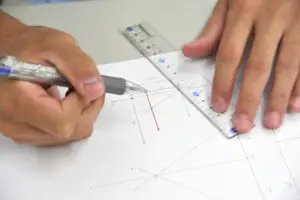

How to measure 2 inches accurately using different tools

To measure 2 inches accurately, you can use several different tools, including a ruler, a caliper, a tape measure, and a micrometer.

Here’s how to use each tool to measure 2 inches accurately:

- Ruler: To measure 2 inches using a ruler, place the end of the ruler against one end of the object being measured and read the measurement at the 2-inch mark.

- Caliper: To measure 2 inches using a caliper, open the jaws of the caliper and place the object being measured between them. Tighten the jaws until they are snug against the object, then read the measurement on the digital or analog display.

- Tape measure: To measure 2 inches using a tape measure, extend the tape measure to the 2-inch mark and place the end of the tape measure against one end of the object being measured. Read the measurement at the other end of the object.

- Micrometer: To measure 2 inches using a micrometer, open the jaws of the micrometer and place the object being measured between them. Tighten the jaws until they are snug against the object, then read the measurement on the micrometer’s scale and thimble. A micrometer typically has multiple scales, so make sure you are reading the correct one for your measurement.

It is important to note that all of these tools require proper use and technique to ensure accurate measurements. Make sure you are using the correct tool for the job and that you are following proper measurement techniques to obtain accurate results.

The significance of 2 inches in various applications

2 inches is a significant measurement in many applications, including woodworking and sewing. Here’s why:

- Woodworking: In woodworking, 2 inches is a common measurement for components such as dowels, screws, and nails. Accurately measuring and cutting these components to 2 inches ensures a precise fit and proper alignment of joints and other components.

- Sewing: In sewing, 2 inches is often used to measure and mark hems, seams, and pleats. Accurate measurement and marking of these components is essential to ensure a proper fit and professional-looking finished product.

- Construction: In construction, 2 inches is a common measurement for pipes, fittings, and other components. Accurate measurement of these components ensures proper installation and function of plumbing, electrical, and HVAC systems.

- Crafts: In various crafts, such as jewelry making and pottery, 2 inches can be used to measure and cut components such as wire, string, and clay. Accurate measurement is essential to ensure the consistent size and shape of these components.

Overall, 2 inches is a significant measurement in many applications and is commonly used in various industries and crafts. Accurate measurement is essential to ensure proper fit, alignment, and function of components, as well as to ensure a professional-looking finished product.

10 objects or items that are 2 inches long

Here are 10 common objects or items that are approximately 2 inches long:

- AA battery

- Paperclip

- Small nail

- Key

- Guitar pick

- USB flash drive

- Lego block

- Bobby pin

- Thumbtack

- Small decorative bead

Please note that these measurements are approximate and may vary slightly depending on the specific brand or model of the item.

How the length of 2 inches compares to other common objects or lengths

2 inches is a relatively small length compared to many other common objects or lengths. Here are some examples of how 2 inches compare to other objects or lengths:

- 2 inches is approximately the length of a standard paperclip.

- 2 inches is about 1/8 of a foot, or 1/24 of a yard.

- 2 inches is shorter than the length of a typical pencil, which is usually around 7 inches long.

- 2 inches is shorter than the width of a standard credit card, which is usually around 3.37 inches.

- 2 inches is about the length of the nail on your pinky finger.

- 2 inches is shorter than the diameter of a standard golf ball, which is usually around 1.68 inches.

- 2 inches is shorter than the width of a standard smartphone, which is usually around 2.5-3 inches wide.

- 2 inches is about half the length of a typical AA battery.

Overall, 2 inches is a relatively small length compared to many common objects or lengths. However, it is still an important and commonly used measurement in various applications, as we’ve seen in earlier examples.

The potential for error when measuring small lengths like 2 inches

When measuring small lengths like 2 inches, there is a potential for error due to a number of factors.

Here are some examples:

- Human error: Even with the most precise tools, there is still the potential for human error when measuring small lengths. This could include inaccurate alignment of the tool, misreading the measurement markings, or simply a slight deviation from the correct measurement.

- Tool accuracy: The accuracy of the measuring tool being used can also impact the potential for error. Cheap or poorly-made tools may not be as precise as higher-quality tools, leading to more potential for error in measurements.

- Environmental factors: Environmental factors such as temperature, humidity, and air pressure can also impact the accuracy of measurements, especially when using certain types of tools like calipers or micrometers.

- Wear and tear: Over time, measuring tools may become worn or damaged, which can impact their accuracy. Regular maintenance and calibration can help to minimize the potential for error due to wear and tear.

Overall, when measuring small lengths like 2 inches, it’s important to use high-quality, well-maintained tools and take care to minimize human error. It’s also important to keep in mind that even with the most precise tools and techniques, there is always a potential for some level of error in measurements.

Tips and tricks for measuring 2 inches with precision and accuracy

Here are some tips and tricks for measuring 2 inches with precision and accuracy:

- Choose the right tool: When measuring 2 inches, and it’s important to choose the right tool for the job. A ruler, tape measure, or digital caliper may all be appropriate, depending on the situation.

- Zero your tool: Before taking your measurement, make sure to zero your tool to eliminate any potential offset or error.

- Use steady pressure: When using a measuring tool like a ruler or caliper, it’s important to use steady pressure to avoid any slippage or movement that could impact the accuracy of the measurement.

- Check the alignment: Make sure that the tool is properly aligned with the object or surface being measured. If the tool is at an angle, it can lead to an inaccurate measurement.

- Take multiple measurements: To ensure accuracy, it’s a good idea to take multiple measurements of the same object or surface and average the results.

- Avoid parallax error: When taking a measurement with a ruler or other tool, make sure to avoid parallax error by viewing the measurement markings from directly above. If the markings are viewed at an angle, it can lead to an inaccurate measurement.

- Consider environmental factors: As mentioned earlier, environmental factors like temperature, humidity, and air pressure can impact the accuracy of measurements. Take care to measure in a consistent environment to minimize any potential impact on accuracy.

By following these tips and tricks, you can help ensure that your measurements of 2 inches are as precise and accurate as possible.

Conclusion

If you want to know how long is 2 inches, then we have got you covered. 2 inches is a small but significant unit of length that is commonly used in a variety of fields, including construction, woodworking, and sewing.

Measuring 2 inches with precision and accuracy requires the use of appropriate tools and techniques, as well as careful attention to factors like tool accuracy, alignment, and environmental conditions. While small in size, 2 inches can have a significant impact on the quality and accuracy of finished products, making precise measurement an essential aspect of many industries and applications.